The aluminum honeycomb sandwich panel features a high quality, colored painted steel sheet face with an aluminum honeycomb core. This ensures a beautiful appearance, an excellent flatness, outstanding sound and thermal insulation, and an excellent flame rating.

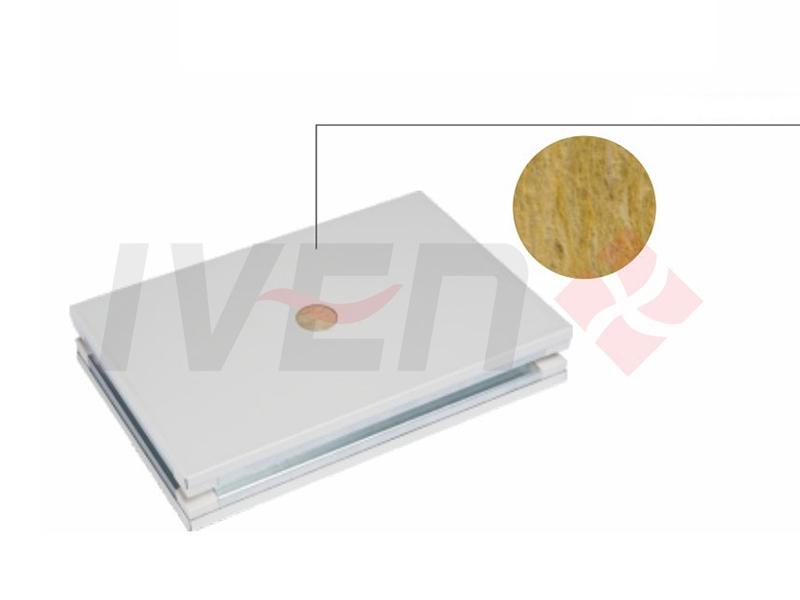

Plaster rock wool sandwich panels are handmade using a colored steel sheet as the two skin layers, plaster board and rock wool as the core, and an iron keel or aluminum alloy frame. It is known for its streamlined appearance and outstanding fireproof performance.

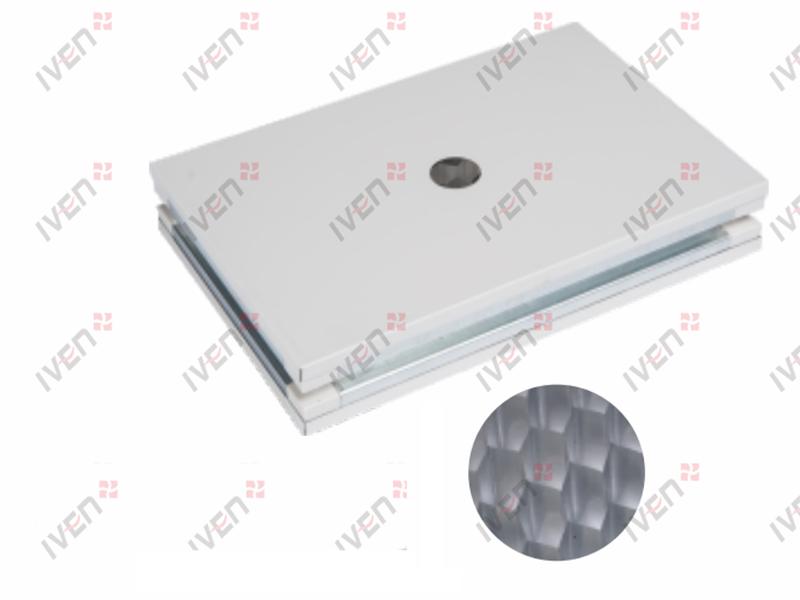

Magnesium honeycomb sandwich panels use high quality colored and painted steel sheets as the face material, a moisture resistance magnesium and aluminum honeycomb as the core material and a special keel support. It is processed via heating, compressing, solidification and other treatments to ensure an attractive appearance, outstanding thermal insulation, and excellent fire resistance. It is also an environmentally friendly cleanroom panel.

Magnesium rock wool sandwich panels use a high quality, color painted steel sheet as the face material, moisture resistant magnesium as the core material, a galvanized steel strip as the side seals and reinforcing ribs, and rock wool as the inner core materials. It is processed using compression, heating and other treatments for a strong load capacity, excellent sealing property, and outstanding fire rating.

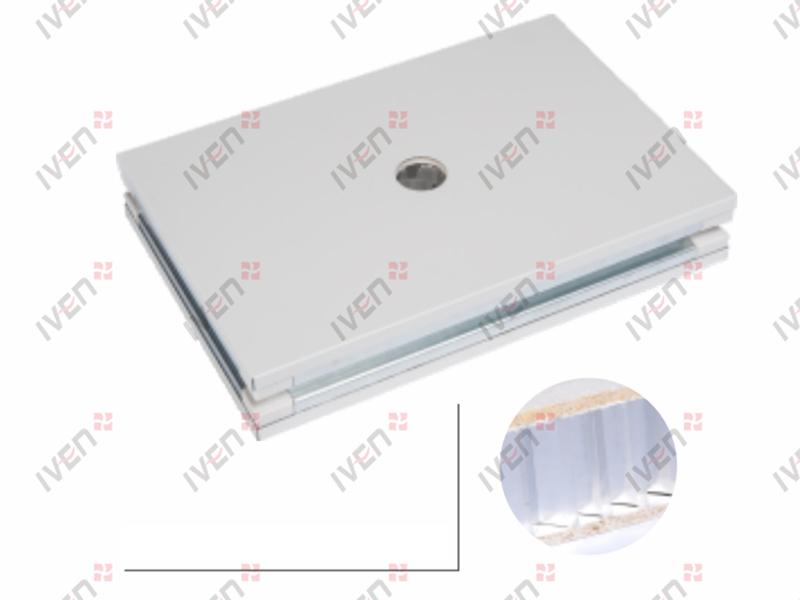

Glass honeycomb cladding panels feature a high quality, colored steel sheet as the face, and a combined, moisture resistant magnesium and paper honeycomb as the core, and galvanized steel strips as the side seals and reinforcing ribs. Made through a compression, heating, and other processes, it features an outstanding flatness, an excellent sound and thermal insulation, and a high flame rating.

Rock wool panel face sheets are a high quality, color painted steel sheet with a handmade rock wool core enclosed by an aluminum or iron keel frame. It features a high cost to performance ration, and an easy, efficient installation, making it ideal for cleanrooms in the pharmaceutical industry.

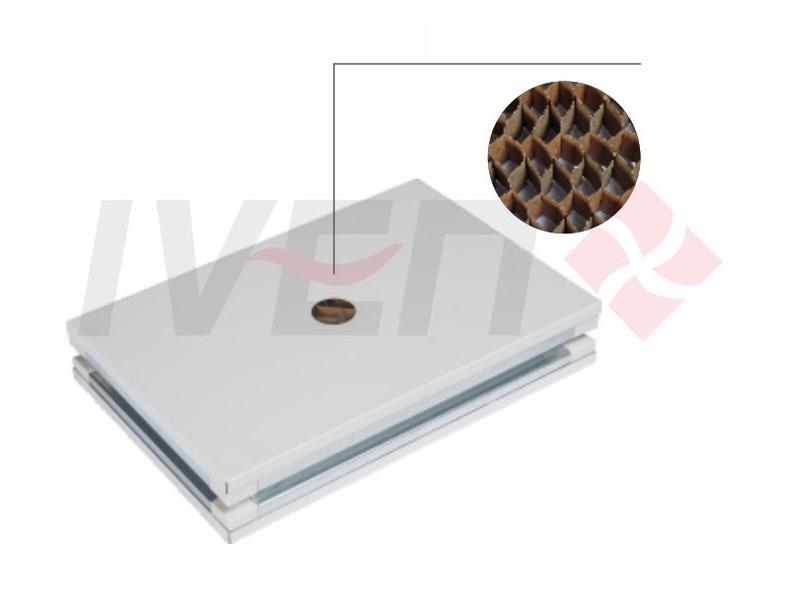

Honeycomb composite panels feature a high quality, color painted steel sheet face and a flame resistant, handmade paper honeycomb core closed by aluminum alloy or an iron keel. This composite panel is perfect for cleanroom applications within the pharmaceutical industry.

The high-pressure laminate HPL sandwich panel uses a high quality, color painted steel sheet as the skin layer, magnesium as the core material, and a magnesium keel as the support. Manufactured using a heating, compressing, glue solidifying and other processes, this sandwich panels features a light weight, high strength, and an excellent water and fire resistance.

We ensure strict quality control for pharmaceutical machinery, complying with ISO9001:2008 and adhering to cGMP, European GMP, US FDA GMP, and WHO GMP standards.

Our equipment is designed to meet diverse production needs, including non-PVC soft bag, PP bottle, and glass bottle IV production lines, as well as automatic ampoule and vial washing, filling, and sealing systems. We also offer solutions for oral liquid processing, dialysis fluid filling, and pre-filled syringe filling and sealing.