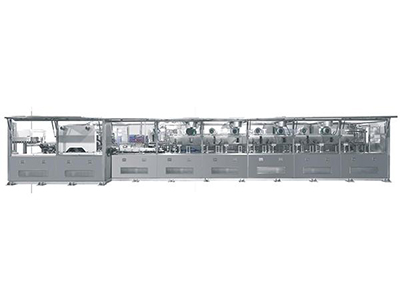

The SR series non PVC infusion bag IV solution production line is our new generation soft bag IV solution production line. It is the result of our years of experience and built based on domestically and internationally advanced technologies.

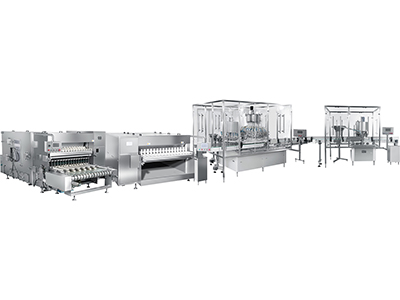

The XGF plastic bottle IV solution washing, filling and sealing production line mainly consists of three sections, including ionic wind washing or ionic wind and water washing section, constant pressure filling section and hotmelt sealing section.

Designed mainly for 50 ml,100 ml, 250 ml and 500 ml IV solution bottles, the glass bottle IV solution production line can perform a variety of procedures, such as ultrasonic rough washing, fine washing, liquid filling, nitrogen filling, stoppering, capping, bottle unscrambling, bottle unloading, lamp checking and labeling.

The unit mainly consists of CLQ vertical ultrasonic vial cleaner, RSM vial sterilizing dryer, KGYX antibiotic vial filling and rubber stopper machine, and FGL capping machine. These machines can be used independently or used in combination with each other, according to customers' actual requirements.

The BXAZ ampoule washing, drying, filling and sealing machine is the pharmaceutical equipment that is newly designed and manufactured using cutting edge technologies and our patent technologies. With reasonable design, compact structure, high automation, reliable operation and high efficiency, the unit has achieved an internationally advanced level.

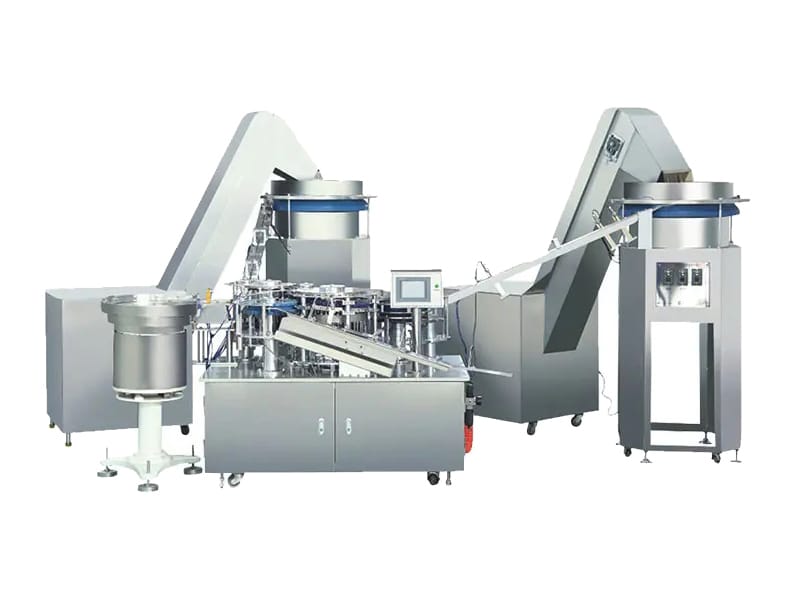

The syringe assembling machine is designed to complete the entire process of producing disposable plastic syringes, from injection molding, printing, silicone oil spraying of the inner wall of the needle tubing, assembly of needles, rubber stoppers, needle tubing, push rods, etc. It also completes sterilizing and packaging.

We ensure strict quality control for pharmaceutical machinery, complying with ISO9001:2008 and adhering to cGMP, European GMP, US FDA GMP, and WHO GMP standards.

Our equipment is designed to meet diverse production needs, including non-PVC soft bag, PP bottle, and glass bottle IV production lines, as well as automatic ampoule and vial washing, filling, and sealing systems. We also offer solutions for oral liquid processing, dialysis fluid filling, and pre-filled syringe filling and sealing.

Our specialists are here to support your pharma projects from start to finish.

Shanghai IVEN Pharmatech Engineering Co., Ltd, established in 2005, has been engaged in pharmaceutical machinery since then. IVEN is a leader in China to provide turnkey solutions to worldwide pharmaceutical company and medical treatment and public health industries by following EU GMP, US FDA and WHO standards.